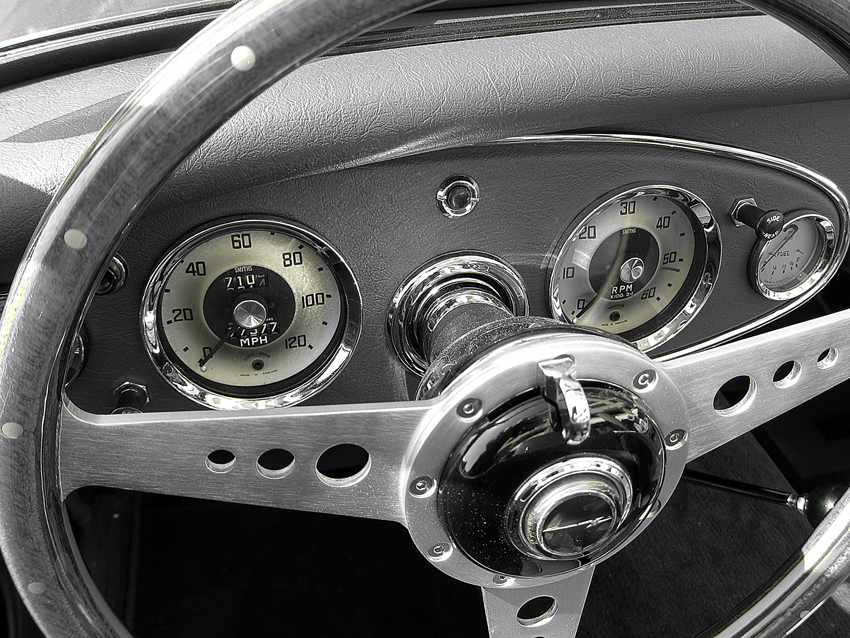

There are two very good reasons to restore the gauges in your collector car. First they don’t work. The other reason is they’re ugly. Ok, not really ugly but they’re certainly not up to the standard you just achieved with your paint and upholstery. You want everything to look as if it just rolled out of the factory. Actually you want it to look better but that’s an entirely different discussion.

Accurate gauges really aren’t all that important. Your engine can’t tell the difference between water that’s 210-degrees and 215-degrees. Sixty-five pounds of oil pressure really isn’t all that different from 60 pounds of pressure. It’s not uncommon for tachometers to be off by 150 rpm. The gauges in your car are not scientific instruments. Most of the gauges in our collector cars simple give us an estimate, which may be all the accuracy we need.

You do though need reliable gauges. You can’t have gauges that report totally different numbers on different days of the week. Reliability refers to the consistency of the measurement. If the gauge says the coolant is 212-degrees will this same gauge report the same thing the following day? Or, will it read 65-degrees? The same is true of the oil pressure gauge. If the gauge says there is 60 lbs. of oil pressure at 3000 rpm will you get the same reading every time you reach 3000 rpms? This consistency, or reliability, is much more important than accuracy.

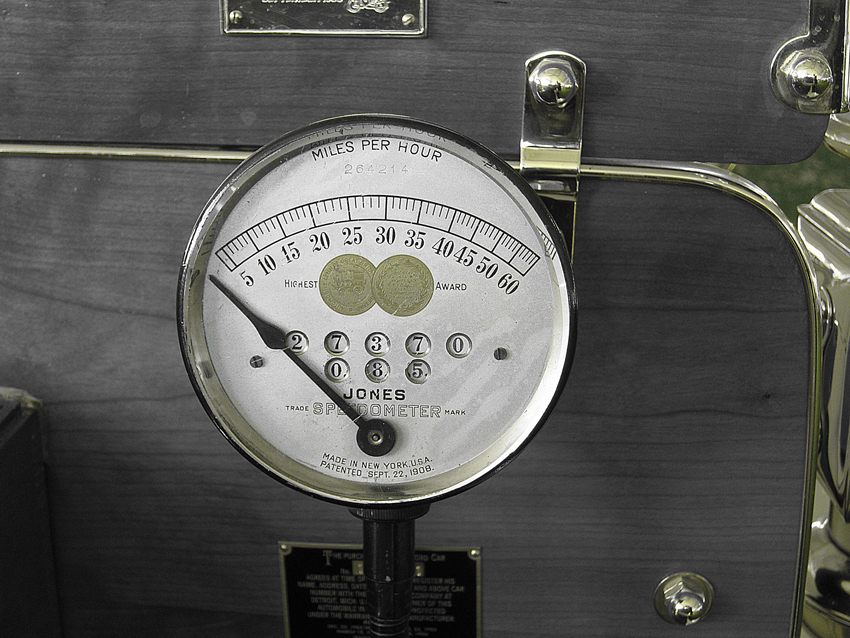

The Gauge Face

This is what you see. It could be faded or it could be scratched. There are two different ways to reproduce a gauge face. Seattle Speedometer, Bob’s Speedometer and Palo Alto Speedometer all use silk screening, also called screen printing, for gauge face restoration. The ink is pushed through the material onto the gauge surface.

When the screening process was first developed people actually used silk. Today everyone uses a polyester material that is described by the mesh count. Mesh count is simply how many holes there are per square inch. An 86-mesh count means there are 86 holes per square inch. A good quality t-shirt will be in the 200 range. When it comes to your gauges you want something above 300 holes per square inch. Ask the restoration shop what they’re using. That’s an indication of the quality you can expect.

Seattle Speedometer and Palo Alto Speedometer also use a technique called pad printing or tampography. Pad printing is more like a rubber stamp. The ink is placed on a pad and then stamped on the face of your gauge. Pad printing can provide tones and details that you can’t achieve with a traditional silk-screening process. Pad printing is going to be more expensive because the process for pad printing is significantly longer than the time it takes to produce a silkscreen gauge face. Everyone agrees that pad printing is superior to silk screening, but are you willing to pay the additional cost? How perfect do you want it? Or need it?

Removal

Don’t do anything until you talk to an expert. Most gauge restoration shops see more customer inflicted damage than damage from normal use. You may think you can fix your own gauges. That usually doesn’t turn out well.

In fact, Seattle Speedometer suggests that you don’t even take your gauges out of the dash until you talk with them. Often times a non-operating gauge is not a gauge problem at all. You could have a bad sending unit or a poor ground. The gauge restoration shops can talk you through the situation. Do not rush into this. Talk to someone first. Then decide on the level of perfection you need in your refurbished gauges.

Sources

Seattle Speedometer – 206.369.5063

Bob’s Speedometer – 800.592.9673

Palo Alto Speedometer – 650.323.0243

Story and photos © 2015 Richard Newton. All rights reserved.